Base oils play a crucial role in ensuring the optimal performance of lubricants and industrial fluids. At Kleen Lube, we pride ourselves on leveraging advanced refining techniques that set our base oils apart from the competition. Our commitment to quality, innovation, and sustainability has made us a trusted supplier of premium base oils in the UAE and beyond.

In this blog, we’ll dive into the refining process that ensures our base oils provide maximum performance, efficiency, and longevity for various industrial applications.

The Importance of High-Quality Base Oils

Base oils are the foundation of lubricants, and their quality directly impacts the efficiency and durability of machinery and vehicles. Low-quality base oils can cause premature wear and tear, reduce fuel efficiency, and contribute to equipment breakdowns. On the other hand, high-quality base oils offer better thermal stability, improved oxidation resistance, and reduced volatility, making them essential for the smooth operation of engines and industrial equipment.

To produce such high-quality base oils, it’s crucial to implement state-of-the-art refining techniques that maximize purity and performance.

Our Advanced Refining Process

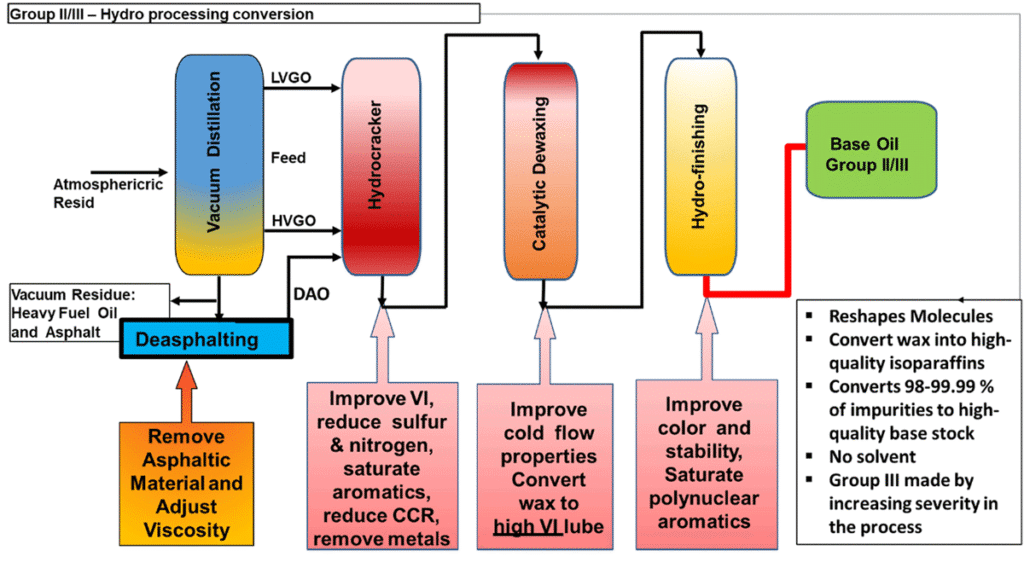

At Kleen Lube, we use advanced refining techniques to produce Group II and Group III base oils, which are known for their high viscosity index and excellent oxidative stability. Here’s a breakdown of the key steps involved in our refining process:

1. Hydrocracking

Hydrocracking is the cornerstone of our refining technique. This process involves breaking down heavier hydrocarbons into lighter, more desirable fractions under high pressure and temperature, using hydrogen. The result is a cleaner and more stable base oil, with improved thermal stability and oxidation resistance. Hydrocracked base oils also have fewer impurities, which enhances their performance and longevity in industrial machinery.

2. Solvent Dewaxing

In order to remove wax and unwanted materials that may cause low-temperature problems, we use solvent dewaxing. This process ensures that our base oils maintain fluidity at low temperatures, making them ideal for a wide range of weather conditions and applications, including automotive and heavy machinery lubricants.

3. Vacuum Distillation

To ensure a high level of purity, we employ vacuum distillation. This technique separates base oils by boiling point, enabling us to extract high-quality fractions while maintaining the integrity of the base oil’s structure. Vacuum distillation produces base oils with lower volatility, making them highly stable under heat and pressure.

4. Hydrotreating and Hydro-finishing

To further improve the base oil’s quality, we use hydrotreating and hydro finishing processes. These processes eliminate impurities like sulfur, nitrogen, and aromatic compounds, ensuring that our base oils have superior cleanliness and stability. Hydro finishing also imparts a high-quality finish, resulting in clearer, purer base oils that perform optimally in lubricants and industrial applications.

Benefits of Our Superior Base Oils

The advanced refining techniques used in our production process translate into multiple benefits for our customers. Here are some of the key advantages of choosing our base oils:

- Enhanced Performance: Our base oils provide excellent thermal stability and oxidation resistance, improving the performance of engines and machinery.

- Longer Equipment Life: By reducing wear and tear, our base oils extend the life span of industrial equipment, vehicles, and machinery.

- Better Fuel Efficiency: High-quality base oils contribute to reduced friction, improving fuel economy and reducing energy consumption.

- Wide Temperature Range: With improved low-temperature fluidity, our oils are suitable for extreme environments, from hot desert conditions to cold climates.

Why Choose Kleen Lube for Premium Base Oils?

At Kleen Lube, we understand the importance of reliable performance and quality in every drop of base oil. Our advanced refining techniques ensure that our products meet the highest industry standards. Whether you are in the automotive industry, heavy machinery, or industrial manufacturing, our base oils are designed to meet your specific needs.

With a focus on sustainability, innovation, and customer satisfaction, we are proud to be a leading base oil supplier in the UAE and the Middle East. By choosing us, you ensure your equipment runs smoothly, efficiently, and with maximum reliability.

Kleen Lube: Leading Base Oil Manufacturer in the UAE

Kleen Lube is a trusted name in the UAE’s base oil manufacturing industry, specializing in high-quality Group II and Group III base oils. Our advanced refining techniques ensure superior performance, stability, and durability for a wide range of industrial and automotive applications. With a commitment to excellence and sustainability, Kleen Lube provides reliable and efficient base oils to meet the diverse needs of businesses across the UAE and beyond.

Author Bio:

Shivam is a passionate writer and blogger with a keen interest in the base oil manufacturing industry in the UAE. With a deep understanding of the market and cutting-edge technologies in oil refining, Shivam shares insights on the latest trends, innovations, and developments in base oil production. His enthusiasm for sustainable practices and quality manufacturing shines through in his writing, helping businesses and industry professionals stay informed and ahead of the curve.